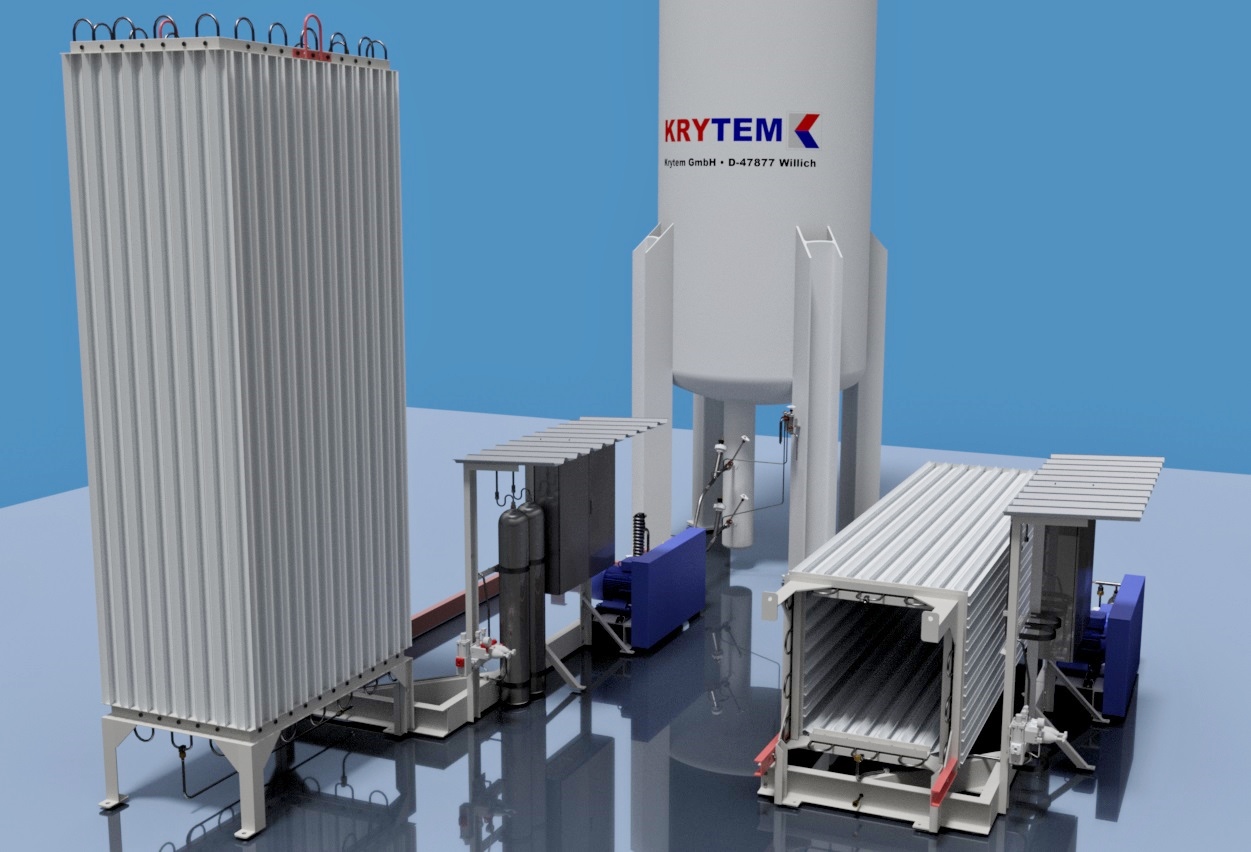

Skid-Mounted High-Pressure Gas Supply Units

Multiple industrial production processes require an intermittent or continuous gas supply at an elevated pressure level from a local cryogenic liquid storage vessel. For such applications KRYTEM developed the HIPREX plant design covering a demand up to several hundred cubic metres an hour at medium to high interface pressure from a single skid-mounted unit that facilitates easy and economic installation, operation and maintenance.

The standard HIPREX unit includes:

- a VSAH type cryogenic reciprocating pumps for thermosyphon tank installation

- a matching CONVEX ambient air heated vaporiser

- a control panel, valves and instruments for semi-automatic operation,

standard design: relay logic with ON/OFF control for buffer charging

including gas temperature monitoring and cold embrittlement trip - a solid dip-galvanised structural steel frame designed for transport and easy local set-up.

Each HIPREX size is designed not to exceed 20 ft ISO container dimensions in order to facilitate an economic transport. HIPREX units for more than 200 Nm³/h feature a pivot at the ground support of the ambient vaporiser that allows to fold the fin-tube unit down for transport purposes.

Options

- an additional pump for redundancy

- monel design for oxygen plants,

featuring TLCM type pumps instead of VSAH and CONVEX HDM type ambient vaporisers - an integrated small size buffer up to design pressure

- a CENTREX AL type electric trim heater for gas temperature increase

- a discharge valve manifold or a pressure regulation unit

- steady flow control with a variable speed drive

- valves and instrumentation for fully automated operation, including automatic switch-over of redundant pumps

- PLC control with a remote support module

- control options for cylinder filling (e.g. limitation of the pressure increase velocity)

Technical Data

| media | HIPREX …N: N2, Ar HIPREX …O: O2 HIPREX …X: LNG / Methane / Natural Gas |

| standard design pressure | 250 / 420 bar (others on demand) |

| process fluid inlet temperature | >-196°C |

| outlet temperature | 0 to 30°C below ambient temperature (higher temp. optional) |

| capacity | up to 10 l/min pump capacity (370 Nm3/h N2 / 460 Nm3/h O2) |

| connections | metal-to-metal threaded connections (others available upon request) |

| materials | Pressurised parts:1.4541, 1.4571 / 2.4360 Frame: S235JR hot-dip galvanised / 1.4301 |