Electric Vaporisers and Gas Heaters

In comparison to process (waste) heat or ambient air electric power is a quite expensive source of energy for thermal processes. However, in many cases it is the only reasonably or reliably available energy and it is easy to handle.

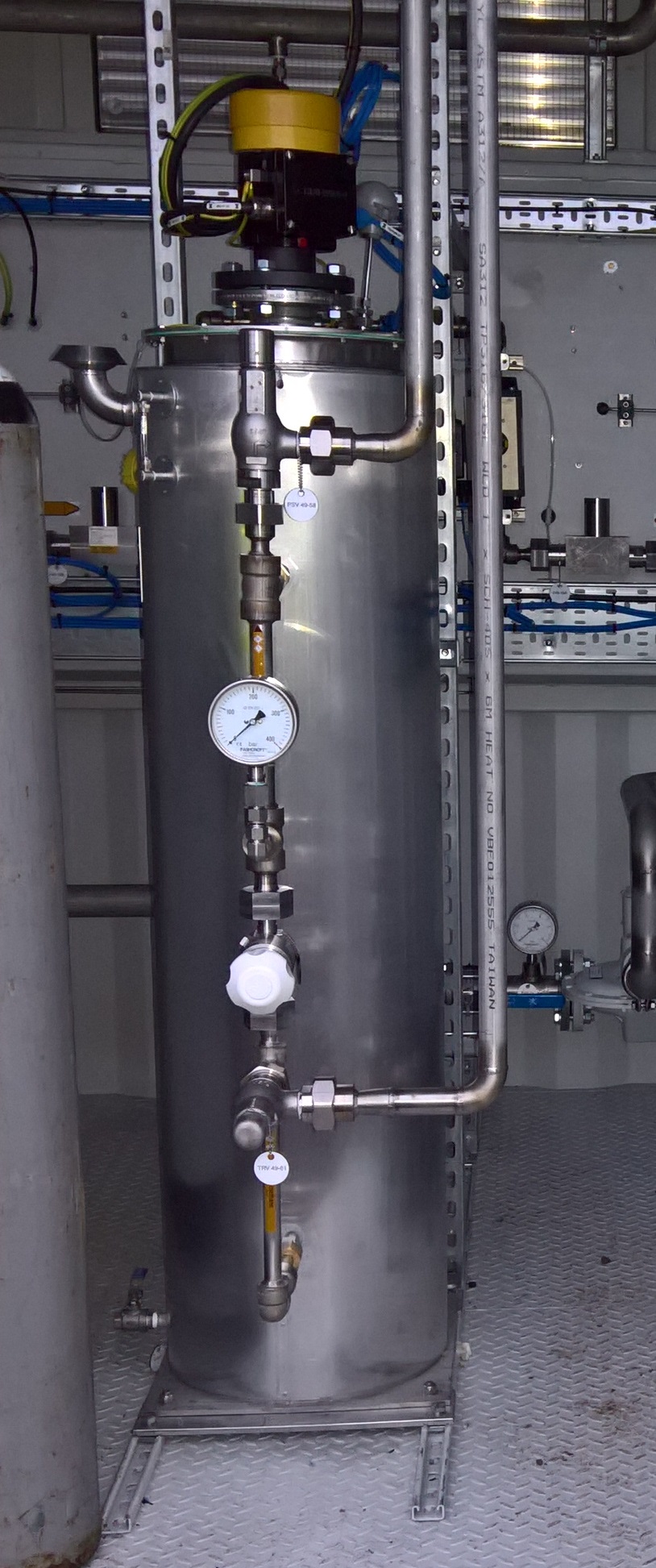

KRYTEM has developed a number of different vaporiser and gas heater concepts which either utilise water or a solid aluminium core for heat transfer to the process medium. Low power gas heaters may also feature direct contact heat transfer for the stainless electrical heater elements.

Ex-proof heater versions according to ATEX directive are available for both gas and dust environments.

Application

- evaporation of small to medium-sized amounts of gas at low to high operating pressures

for the supply of processes and the filling of industrial gases - heating of gas downstream from evaporators that extract thermal energy from the ambient air

- evaporation / heating of gas without connection to heated water plumbing or the use of fuel

- models approved for operation in potentially explosive atmospheres are available

Design Features

- compact, space-saving design

- no direct contact between the process medium and the heating elements, resulting in minimal wear

- permanent, non-pressurized liquid or solid heat carrier on the inside

- configured to be mounted vertically (standard) or horizontally (some designs)

Technical Data

| media | N2, O2, Ar, CO2, He, H2, CH4, LNG |

| inlet temperature | -269°C to -20°C |

| outlet temperature | 0 to +60°C ±15°C (±1°C with thyristor control) |

| max. operating pressure |

up to 800 bar |

| capacity | up to 3000 Nm3/h – up to 300 kW (higher capacity available per request) |

| heat carrier | water or water-glycol bath (CENTREX WBH, PAREX E) aluminum core (CENTREX AL) |

| control | temperature reading via a resistance sensor in the outlet; dual-step or multi-step control, or microprocessor controlled PI control |

| overheat protection | integrated in heating element |

| power supply | 230 / 400 V – 50 Hz (standard) |

| connections | flanged or threaded connections |

| materials | 1.4541, 1.4571, aluminum |

| insulation | dependent upon gas temperature and ambient temperature |